Scented Candle Supplier

Hand-Poured vs Mass-Produced Scented Candles: What’s the Difference?

Many buyers feel confused when candles look similar but perform very differently. The production method often explains this gap, yet it’s rarely visible at first glance. Understanding hand-poured vs mass-produced candles helps businesses make smarter purchasing decisions.

Hand-poured candles are made in small batches with individual attention, while mass-produced candles use automated processes for large volumes. The production method affects scent quality, burn performance, and overall value.

The choice between these approaches impacts everything from fragrance intensity to customer satisfaction. Let’s examine the key differences that matter for your business.

How are hand-poured candles made differently?

Hand-poured candles represent the artisan approach to candle making. Each candle receives personal attention throughout the creation process.

Hand-poured candles are crafted in small batches where each candle is individually poured and monitored for optimal wax temperature and fragrance blending. This careful process ensures superior scent throw and burn quality.

The small-batch advantage

The hand-poured process begins with careful wax melting. Artisans heat soy wax to precise temperatures (130-165°F) before adding fragrance oils. This temperature control is crucial for proper scent binding. Mass-produced candles often skip this precision, heating wax much hotter for faster production.

Step-by-step hand-pouring process

The handmade approach involves multiple quality checkpoints that differentiate hand-poured vs mass-produced scented candles significantly.

| Production Step | Hand-Poured Method | Quality Impact |

|---|---|---|

| Wax Melting | Small batches, manual temperature check | Prevents fragrance oil burning |

| Fragrance Adding | Added at precise temperatures, hand-stirred | Maximizes scent retention |

| Pouring Technique | Individual container pouring | Eliminates air pockets |

| Wick Placement | Hand-set and centered for each candle | Ensures even burning |

| Cooling Time | Natural cooling over several hours | Prevents cracking, frosting |

| Curing Period | 5-14 day resting period | Enhances fragrance development |

Why curing time matters

After pouring, hand-poured candles cure for several days to weeks. This allows fragrance oils to fully bind with wax molecules, resulting in cleaner, stronger scent throw. The extended curing process represents a key quality differentiator that mass production often sacrifices for speed.

The human element in quality control

Each hand-poured batch undergoes visual inspection and test burns. Artisans check for sinkholes, frosting, or poor wick placement. This hands-on approach catches defects that automated systems might miss, ensuring consistent quality that businesses can rely on.

What defines mass-produced scented candles?

Mass-produced scented candles prioritize efficiency and volume over individual craftsmanship. They’re designed for large-scale distribution and competitive pricing.

Mass-produced scented candles are manufactured using automated equipment that produces thousands of units daily. This efficiency enables lower prices but often sacrifices some quality aspects found in hand-poured alternatives.

The economics of scale in candle production

Mass production relies on high-volume machinery that can produce 5,000-10,000 candles daily. This scale creates significant cost advantages but limits customization opportunities that many businesses now seek.

Typical mass-production process

Understanding the automated workflow highlights key differences between hand-poured vs mass-produced scented candles.

| Production Stage | Mass-Production Method | Trade-Offs |

|---|---|---|

| Wax Preparation | Bulk melting in industrial tanks | Faster but less temperature control |

| Fragrance Mixing | Automated dosing systems | Consistent but may use less oil |

| Pouring | Assembly line filling | High speed but potential air traps |

| Cooling | Accelerated cooling tunnels | Faster setup but possible imperfections |

| Quality Checks | Statistical sampling | Misses individual candle defects |

Materials and cost considerations

To maintain competitive pricing, mass-produced candles often use paraffin wax or soy-paraffin blends rather than pure natural waxes. They typically use lower fragrance oil concentrations (5-6% vs 8-10% in premium hand-poured candles), affecting scent strength and longevity.

Consistency challenges in large batches

While automation aims for consistency, large batches can develop variations. Fragrance oil might settle unevenly in storage tanks, or wax temperature fluctuations can affect scent binding. These factors contribute to the quality variance sometimes seen in mass-produced products.

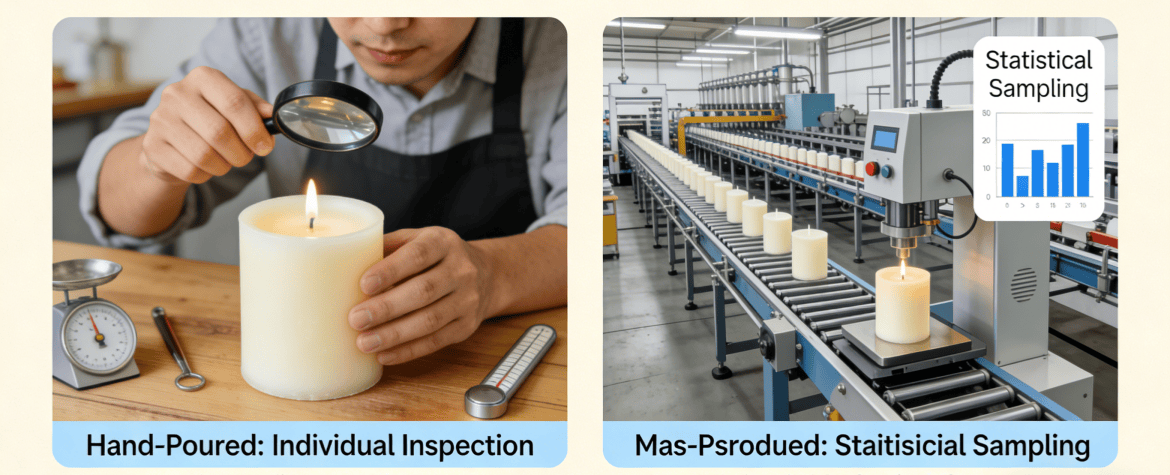

Which candle type offers better quality control?

Quality control differs significantly between production methods. The hand-poured vs mass-produced scented candles debate often centers on which approach delivers more reliable quality.

Hand-poured candles typically offer superior quality control through individual inspection of each candle, while mass-produced candles rely on statistical sampling that may miss individual unit defects.

The artisan quality advantage

Hand-poured candle makers examine each candle for multiple quality indicators. This meticulous approach catches issues that mass production might overlook.

| Quality Factor | Hand-Poured QC | Mass-Produced QC |

|---|---|---|

| Visual Defects | Each candle inspected | Sample checking (1-5% of batch) |

| Wick Placement | Hand-centered and verified | Machine-set, occasional misalignment |

| Scent Consistency | Small batch consistency | Batch-to-batch variation possible |

| Burn Testing | Regular test burns | Occasional sample testing |

| Adjustment Speed | Immediate corrections | Requires machine recalibration |

Testing methodologies compared

Hand-poured artisans test burn candles from each batch, monitoring wax pool development, burn evenness, and fragrance release. Mass producers often rely on accelerated testing that may not replicate real-world conditions, potentially missing performance issues.

Defect rates and customer satisfaction

With individual inspection, hand-poured candles typically have defect rates below 2%. Mass-produced candles, relying on statistical sampling, may have higher defect rates that only become apparent after customer complaints. For B2B buyers, lower defect rates mean fewer returns and higher customer satisfaction.

The fragrance quality difference

The quality gap is most noticeable in fragrance performance. Hand-poured candles’ longer cure times and temperature-controlled processes yield stronger, truer scents that enhance the user experience and support brand reputation.

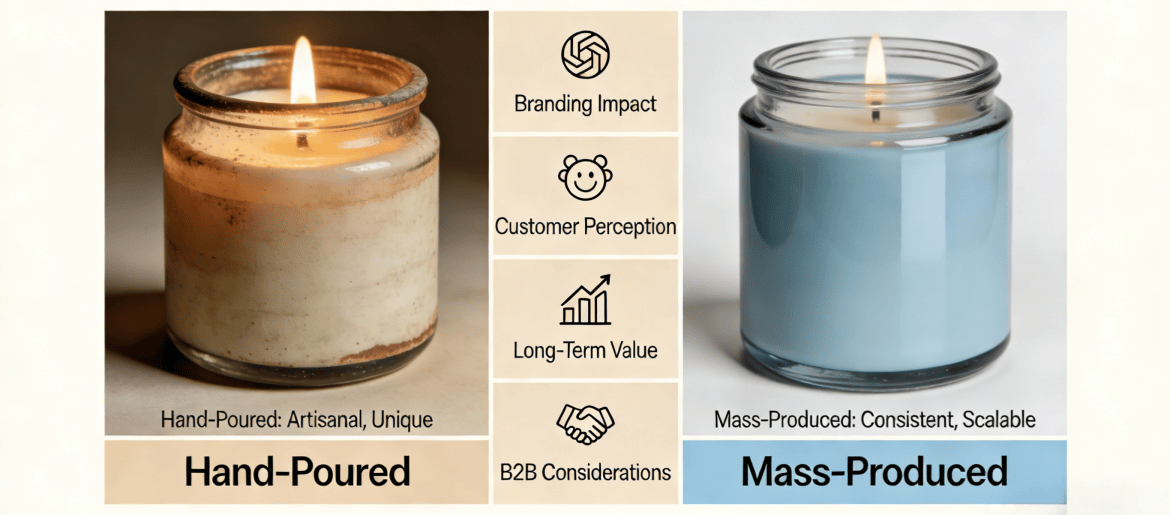

Why does production method matter to B2B buyers?

The hand-poured vs mass-produced scented candles decision has significant business implications beyond initial cost considerations. Production method affects branding, customer perception, and long-term value.

The production method matters to B2B buyers because it impacts brand positioning, customer satisfaction, repeat business potential, and overall value proposition in competitive markets.

Brand storytelling and market positioning

Hand-poured candles support artisanal, premium brand stories that justify higher price points. Mass-produced candles align with accessible, volume-driven branding strategies. The choice should align with your target market and brand identity.

Customer experience differences

The production method directly affects end-customer satisfaction through several key factors that influence repeat business and brand loyalty.

| Customer Experience Factor | Hand-Poured Impact | Mass-Produced Impact |

|---|---|---|

| Fragrance Strength | Stronger, more complex scents | Variable, sometimes weaker |

| Burn Time | Longer, more even burns | Shorter, potential tunneling |

| Visual Appeal | Artisanal character, uniqueness | Consistent but generic appearance |

| Perceived Value | Higher, premium perception | Lower, commodity perception |

| Brand Story | Craftsmanship narrative | Efficiency and accessibility story |

Business operational considerations

B2B buyers must weigh several practical factors when choosing between production methods for their operations.

| Business Consideration | Hand-Poured Advantages | Mass-Produced Advantages |

|---|---|---|

| Minimum Order Quantity | Flexible, smaller batches | Higher MOQs required |

| Customization Options | High flexibility for exclusives | Limited to existing designs |

| Delivery Speed | Longer lead times for quality | Faster turnaround |

| Supply Consistency | Subject to artisan capacity | More reliable volume supply |

| Margin Potential | Higher margins possible | Lower margins, volume focus |

Long-term brand building

Hand-poured candles often create stronger emotional connections with customers, leading to better brand loyalty. Mass-produced candles serve price-sensitive markets where consistent supply matters more than artisanal qualities. The decision should align with your overall business strategy and target market positioning.

The customization advantage

Hand-poured production allows greater customization flexibility, enabling businesses to develop signature scents, limited editions, and branded experiences that differentiate them in competitive markets. This adaptability is particularly valuable for hotels, spas, and specialty retailers seeking unique product offerings.

Conclusion

The hand-poured vs mass-produced scented candles decision involves clear trade-offs. Hand-poured offers superior quality, customization potential, and branding advantages that support premium positioning. Mass-produced provides cost efficiency and volume consistency for price-sensitive markets. Understanding these differences ensures B2B buyers select the right option for their specific business needs, target customers, and brand strategy.